Belt Conveyors & Feeders

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.

Flexible Wall Belt Conveyors

Ward custom designs and manufactures flexible walled belt conveyors. These have proven to be effective in space constraint and high angle conveying requirements reducing the number of conveying equipment and transfer points. Most common conveyor shapes include straight incline, “L” and “S”, but almost any configuration is possible.

Bucket Elevators

Ward manufacturers a complete line of Bucket Elevators using belts or chain including centrifugal and continuous discharge designs. Special bucket elevators include centrifugal Type “E”, mill type and super capacity. Call us with your requirements.

Apron Conveyors & Feeders

Ward Apron Conveyors & Feeders are designed to be durable in the most difficult environments including hot casting / forgings, lead battery recycling, etc. Ward Apron Conveyors & Feeders are available in standard and heavy duty and are used where other modes of conveying cannot be used.

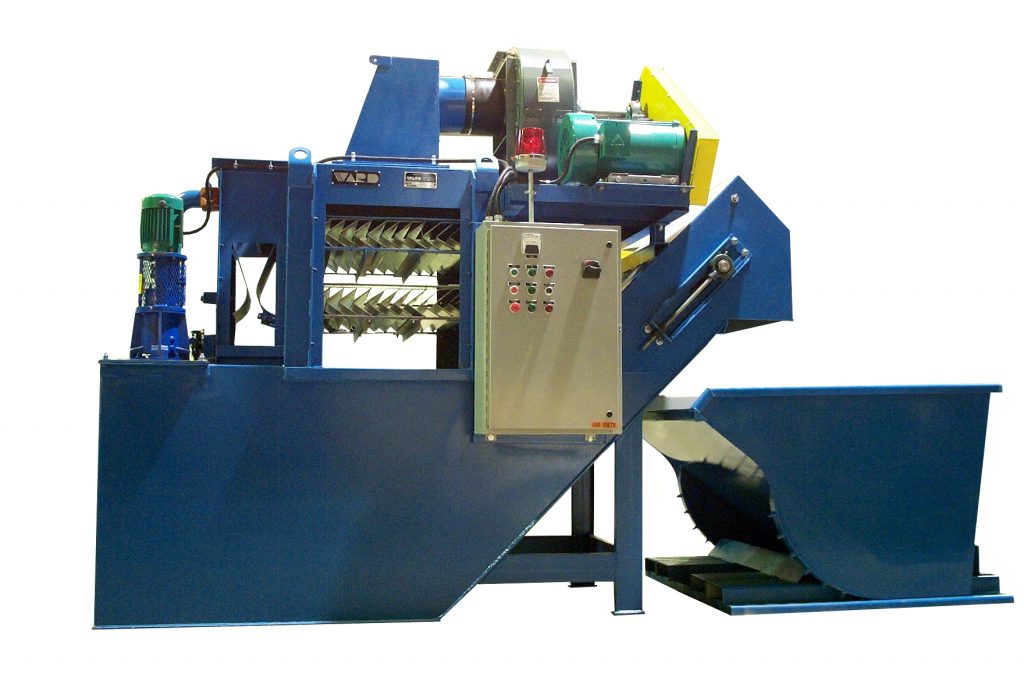

Vibrating Conveyors & Feeders

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.

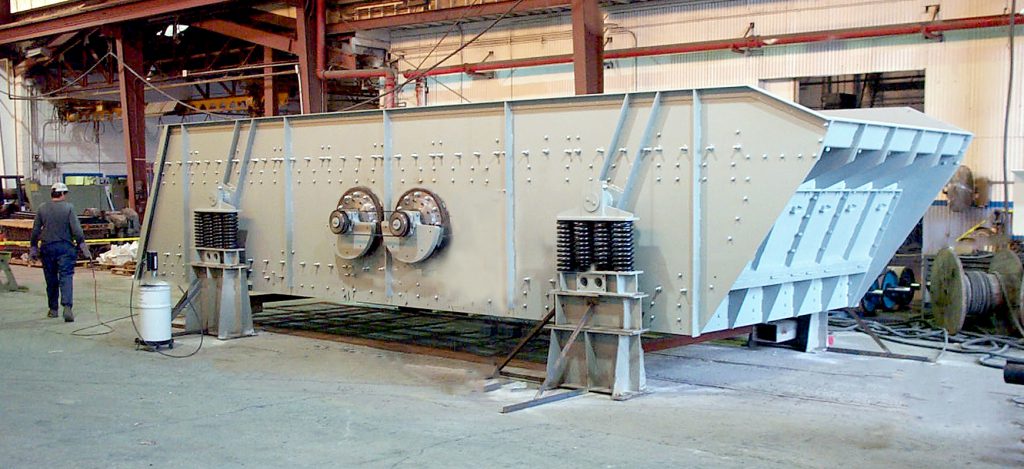

Vibrating Screens & Shakeouts

Ward has many years of experience in the design of high performance vibrating screens. They are available in models ranging from 3’ x 6’ to 8’ x 24’ in single, double and triple deck configurations. Suspension or base mounting is employed depending on the intended application.

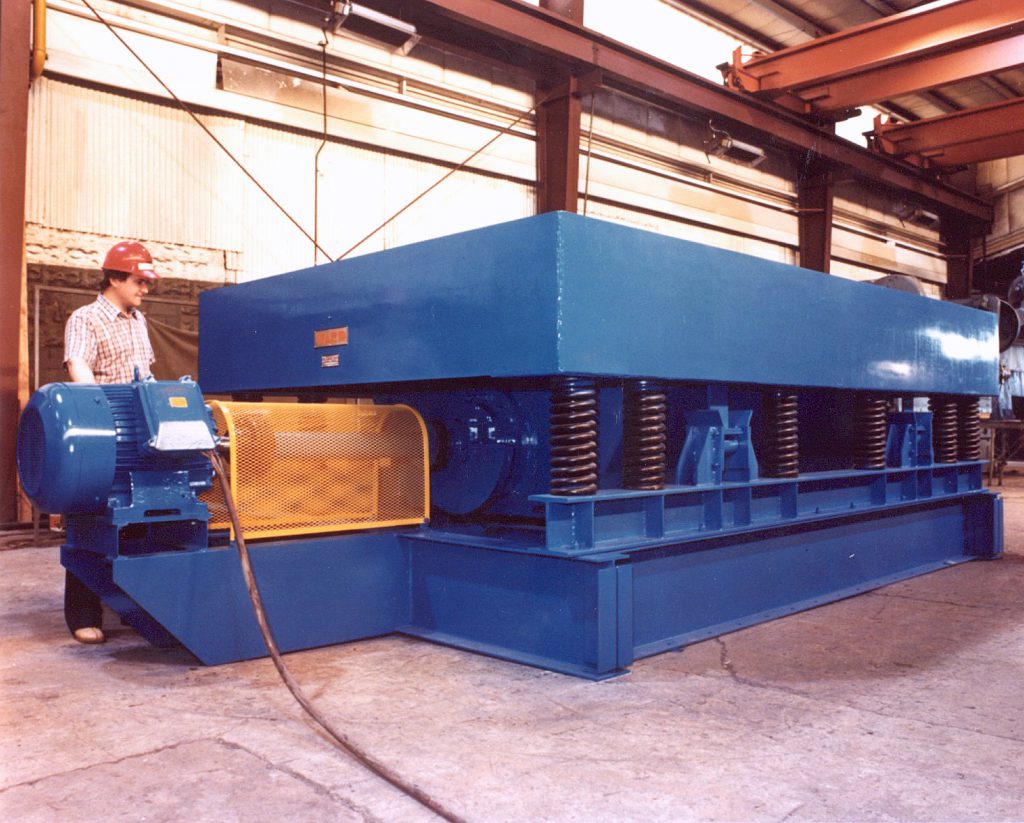

Ward Shakeouts are designed and manufactured to provide long, trouble-free service, separating sand and castings as quickly and gently as possible, preventing impact damage to the castings. These units are available in both Non-Discharging and Self-Discharging models and in a wide range of sizes. Various speed stroke combinations are also available to suit the customer’s specific requirements.

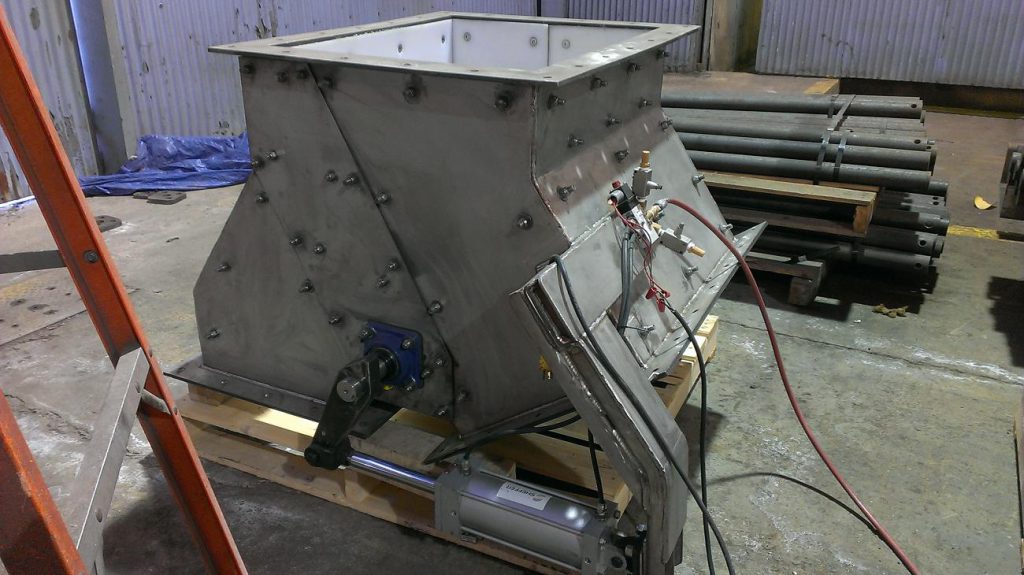

Gates, Transfers & Accessories

Ward can design and manufacture all your bulk storage, transfer and accessories.

Items Include:

- Steel Silos & Storage Bins

- Steel Hoppers & Chutes

- Single & Duplex Gates

- Cut-off Gates & Diverter Gates

- Slide Gates and Rack & Pinion Gates

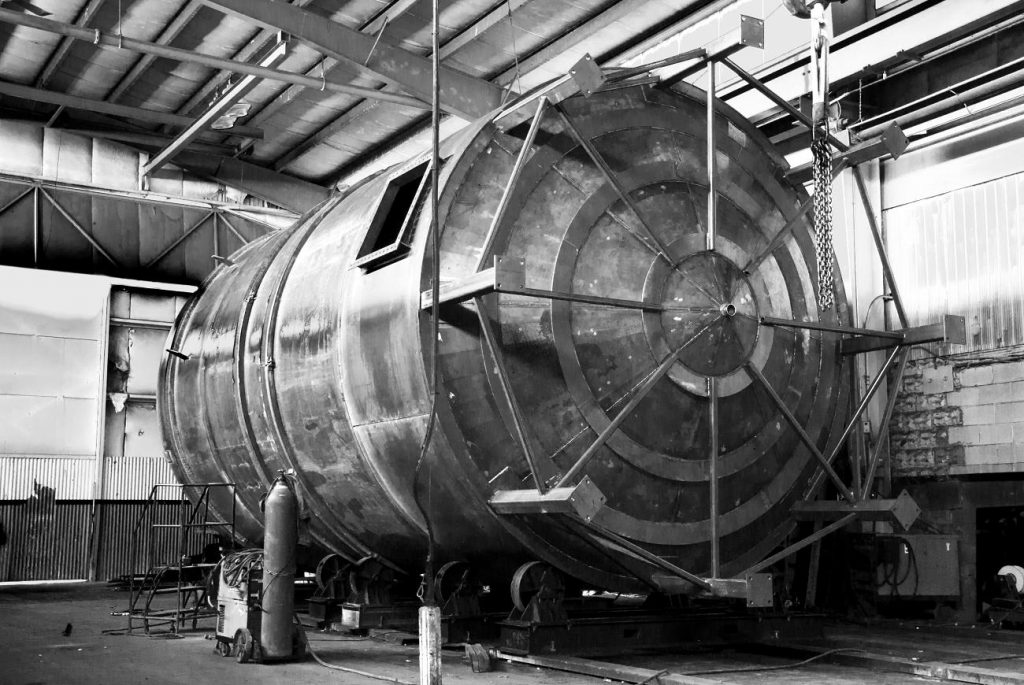

Devansco Wet Air Scrubbers

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.

Bins & Hoppers

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.

Truck Bodies

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.

Customer Engineered Fabrications

Ward designs and manufactures several customized belt conveyors and feeders for many service industries. Belt conveyor designs include stackers, trippers, distribution and shuttles in different profiles and with different options. Belt Feeder designs include fixed and adjustable rates, hoppers with liners, adjustable flow gates and self relieving skirts. Almost all are designed and built to the unique requirements of each project.